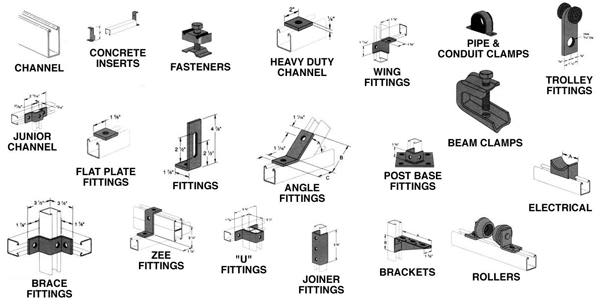

Globestrut Products

GLOBE

STRUT® Metal Framing satisfies a broad range of needs as

a bolted framing system for mechanical, electrical and industrial applications.

Designed and manufactured to exacting standards, it simplifies and reduces

cost of structural fabrication and makes possible in-plant construction

of structural frames for machinery, racks and pipes. Metal framing also

offers a combination accessible surface raceway for support for lighting

fixtures and electrical equipment. When embedded in monolithic concrete,

this economical framing provides a convenient flush mounting in walls, ceilings

and floors.

Regular

channel with a solid continuous web are used for general framing

requirements. GLOBE STRUT®is available in a multitude of channel sizes,

lengths, and finishes and is cold-formed from mild steel to meet light,

medium and heavy load requirements.

Knockout

channel have 7/8" dia. knockouts 6" o.c. starting 3"

from the end. To specify, add suffix "KO" to product number.

Punchout channel have 9/16" dia.

holes spaced 1 7/8" o.c. starting from 13/16" from end. Prepunched

holes offer added flexibility for attaching channel and fixtures. To specify,

add suffix "PO" to product number.

Punchout channel have 9/16" dia.

holes spaced 1 7/8" o.c. starting from 13/16" from end. Prepunched

holes offer added flexibility for attaching channel and fixtures. To specify,

add suffix "PO" to product number.

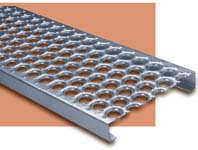

Slotted Hole channel have 9/16"

dia. x 7/8" slotted holes spaced 2" o.c. starting 1" from

end. Slotted holes allow minor bolt adjustment and match spacing on many

fittings. To specify, add suffix "SH" to product number.

Slotted Hole channel have 9/16"

dia. x 7/8" slotted holes spaced 2" o.c. starting 1" from

end. Slotted holes allow minor bolt adjustment and match spacing on many

fittings. To specify, add suffix "SH" to product number.

Slotted channel have 13/32" x 3"

slots spaced 4" o.c. starting 1 7/8" from end. Ideal support for

pipe, tube, conduit and cable tray. To specify, add suffix "SL"

to product number.

Slotted channel have 13/32" x 3"

slots spaced 4" o.c. starting 1 7/8" from end. Ideal support for

pipe, tube, conduit and cable tray. To specify, add suffix "SL"

to product number.

Double Slotted channel have 7/8"

x 9" slots plus two 9/16" round holes per 12" module. Double

slots permit space-saving support for pipe, tube, conduit and cable tray

above and below. Since it is slotted to accept Globe Strut® Universal

Pipe Clamps on both sides, it works more efficiently. To specify, add suffix

"DS" to product number.

Double Slotted channel have 7/8"

x 9" slots plus two 9/16" round holes per 12" module. Double

slots permit space-saving support for pipe, tube, conduit and cable tray

above and below. Since it is slotted to accept Globe Strut® Universal

Pipe Clamps on both sides, it works more efficiently. To specify, add suffix

"DS" to product number.

Continuous

Concrete Inserts are designed for convenient nail-up to formwork.

If attached to the pouring face of forms, they provide a permanent, continuous

mounting slot flush with the concrete surface. A punched portion of the

channel web provides protruding "ears" for wire-tying reinforcing

bars at 4" increments and mechanically anchoring the channel in the

concrete. A plate fills the void created by the "ear" opening

to keep concrete from seeping into the channel. Inserts are furnished either

ready-to-use, with end caps and closure tape installed, or with caps and

tape separately for field-cut lengths.

Powerstrut Menu Links

Power Engineering

Co. Inc. 420 Boston Turnpike Shrewsbury, MA 01545 Phone: 1-800-274-1303 Fax: 508-842-9833 |

||||